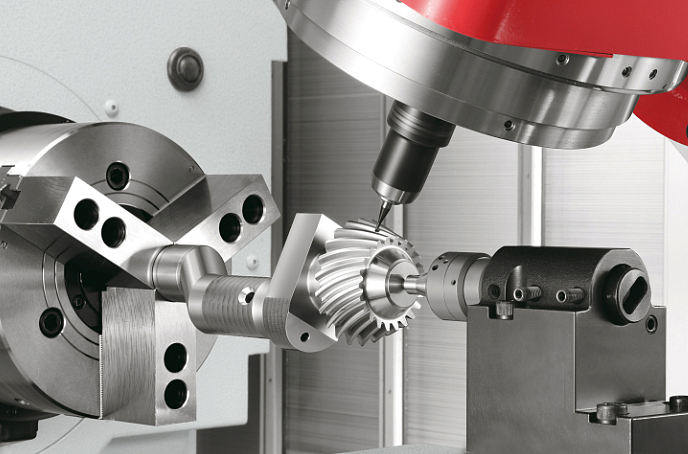

Machined parts using processing method

Name:Special Report Date:2020-04-15 11:52

Machined parts refer to the whole process of making the shape, size, relative position and nature of the blank into qualified parts according to the drawings and dimensions of the drawings using mechanical processing methods. The machining process is the work that the technicians need to do before processing. Avoid processing mistakes during the processing and cause economic losses.

Machining process flow is the step of manufacturing or processing of workpieces or parts. The process of mechanical processing is used to directly change the shape, size and surface quality of the blank, so that the process of making it into parts is called machining process flow. For example, the processing flow of a common part is roughing-finishing-assembly-inspection-packaging, which is a general process of processing. The mechanical processing technology is to change the shape, size, relative position and nature of the production object on the basis of the process to make it into a finished product or semi-finished product. It is a detailed description of each step and each process. For example, as mentioned above, the rough Processing may include blank manufacturing, grinding, etc., finishing may be divided into turning, fitter, milling machine, etc., each step will have detailed data, such as how much roughness to achieve, how much tolerance to achieve. The technical personnel determine the process to be adopted according to the number of products, equipment conditions and the quality of the workers, and write the relevant content into a process document. Such a document is called a process specification. This is more targeted. Each factory may be different because the actual situation is different. In general, the process flow is the program, the processing process is the detailed parameters of each step, and the process specification is a specific processing process written by a factory according to the actual situation.